Inspiration, Tips and Advice

Embossed vs Debossed: A Printer’s Guide

If you’re looking for a way to elevate and add some depth or sophistication to the visual appeal of your printed materials, then embossing and debossing are two classic techniques to consider. Whether you’re creating a premium Business Card, custom Stationery, Packaging or working with personalised materials, understanding the differences between the two finishes is essential.

This guide will explain what embossed and debossed printing really means, explore the benefits and drawbacks of each, and help you decide which is right for your next project and how you can place your order through our Bespoke Service.

Image Credit: Printed.com

What Does Embossed Mean?

Embossing is a printing technique that creates a raised design, text, or logo on a material like paper or card. Think of it as a 3D effect that lifts part of the surface.

This is achieved using a custom metal die (also known as an embossing stamp) and a matching counter-die. The material is placed between them, and pressure is applied from underneath, forcing the design upwards. The result is a tactile, three dimensional impression that adds a layer of luxury and makes key elements stand out.

The Meaning of Embossed in Print

In the world of print, the embossed meaning is synonymous with elegance and quality. It elevates flat designs by adding physical depth and texture. When you hand someone an embossed business card, they immediately notice the difference. The raised logo or name feels premium and memorable.

Common Uses for Embossing

- Business Cards: An embossed logo or name can make your card pop, leaving a lasting impression on potential clients.

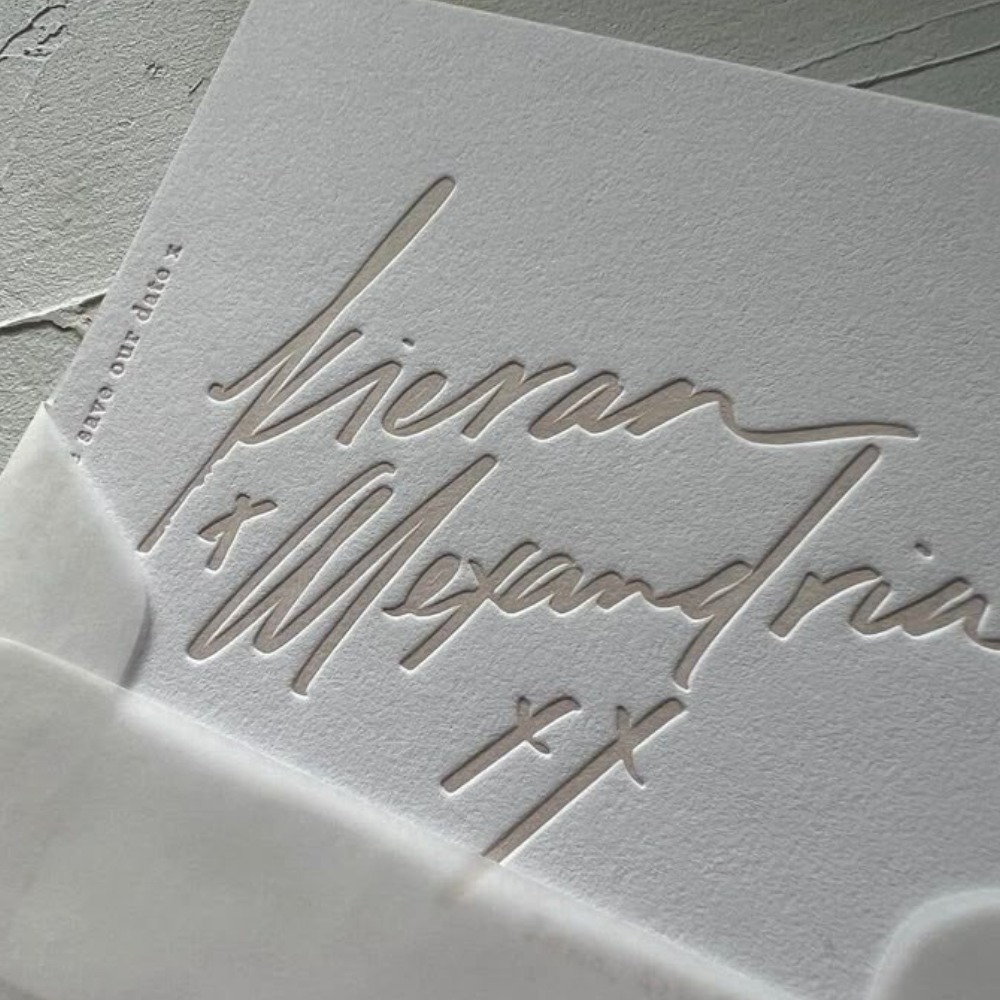

- Wedding invitations: Embossed Wedding Invitations can add a sense of style and romance, setting the tone for the big day.

- Packaging: Many premium brands use embossed logos or emblems on their product packaging to signal quality and luxury.

- Certificates: Embossing is often used on official documents and certificates to add authenticity and a mark of distinction.

Image Credit: Mazii Collection

What is Debossing?

Debossing is the opposite of embossing. Instead of raising the design, it involves pressing it into the material so it sits below the surface. Like embossing, this technique uses a metal die to create the impression, but the pressure is applied from the top, creating an indentation.

Debossing can be done with or without ink. A “blind” deboss (without ink) offers a subtle, refined look that speaks of quiet confidence. Alternatively, combining it with ink or foil stamping can add both colour and dimension, creating a rich, textured appearance.

Debossed vs Embossed: The Core Difference

The main distinction between the two techniques lies in the direction of the impression. It’s quite simple when you break it down:

- Embossed = The design is raised up from the surface.

- Debossed = The design is recessed or indented into the surface.

While both techniques create a tactile experience that engages the sense of touch, they deliver very different visual results. An embossed design physically comes towards you, catching the light and casting a subtle shadow. A debossed design, on the other hand, creates depth by drawing you into the material.

Image Credit: Cedar and Grey Paper Co

The Pros and Cons of Embossing

Let’s take a closer look at the advantages and potential drawbacks of choosing an embossed finish for your next print project.

Benefits of Embossing

1. Tactile Luxury

Embossing adds a tangible texture that people can feel. This physical interaction makes your printed materials more memorable and enhances the perception of your brand as high-quality.

2. Visual Hierarchy

You can use embossing to draw the eye to the most important information on your design, like your brand name, logo, or a key message. This creates a natural visual hierarchy that guides the reader.

3. Premium Appeal

Finishes like gold foil or coloured foil embossing radiate luxury. This is ideal for high-end products, special events like weddings, or official documents like certificates.

Image Credit: Becky Lord Designs

Drawbacks of Embossing

While it offers a stunning finish, embossing does come with a few considerations to keep in mind.

1. Higher Cost

The process requires a custom die to be created, which can make it more expensive than standard flat printing. However, this is a one-off cost for the die, making reorders more affordable.

2. Not Ideal for Small Details

Embossing works best with bold, clean designs. Very fine lines or small, intricate text may lose definition in the process.

3. Reverse Imprint

Standard embossing leaves an indented impression on the back of the material (the “debossed” reverse). If a clean back surface is essential, you may need to layer another piece of card behind.

Image Credit: Becky Lord Designs

The Pros and Cons of Debossing

Debossing can be just as impactful as embossing, offering a different style to your design.

Benefits of Debossing

Debossing can be just as impactful as embossing in print, especially when used creatively.

1. Elegant Subtlety

This technique offers a more understated and refined finish. It’s perfect for brands that want to convey sophistication without being overly flashy.

2. Works Well with Ink and Foil

It pairs beautifully with ink or foil stamping. A printed or foiled design that’s also debossed gains added depth and interest, creating a fantastic multi-dimensional effect.

3. Premium Finish

It truly adds a high-end, professional touch to your printed materials. You’ll find it brings a subtle elegance that genuinely elevates the final product.

Image Credit: Ivy and Stone

Drawbacks of Debossing

There are a few limitations to keep in mind.

1. Higher Cost

Like embossing, this process requires a custom die, which can make it more expensive than standard flat printing. However, the die is a one-time cost, making subsequent reorders more affordable.

2. Less Tactile Impact

While still textured, a debossed design may not feel as prominent under your fingers as a raised, embossed one.

3. Can Be Too Subtle

On certain materials or in some lighting conditions, a blind deboss might not be easily visible, which could be a drawback if brand recognition is your main goal.

Choosing Between Embossed and Debossed

Here’s a quick reference guide to help you decide between embossed and debossed finishes:

| Feature | Embossed | Debossed |

| Design effect | Raised above surface | Pressed below surface |

| Tactile impact | Strong | Moderate |

| Compatibility | Paper, card, leather | Paper, card, leather |

Combining Embossing and Debossing

Yes, you can have both! Known as combination embossing, this technique uses embossing and foil stamping or debossing in tandem for stunning results. Think embossed gold lettering paired with debossed borders, or hand embossing around a printed logo. The results can be dramatic, tactile, and incredibly polished.

Image Credit: Evdoro

What is a Leather Embossing Stamp?

For leather or leather like materials items, such as Notebooks, a leather embossing stamp is used to create a permanent raised design on the surface. Heat and pressure are applied to press the design into the leather, often using metal dies or custom stamps. This can be done with or without foil, and is popular for monograms, logos or decorative patterns.

Hand embossing on leather is a skilled craft often used for one-of-a-kind or artisanal goods. Whether you’re using initials, logos, or patterns, leather embossing adds character and longevity to your items.

Choosing Embossing Fonts

When creating designs for embossing, it’s important to choose the right typography. Here are a few tips:

Best Fonts for Embossing:

- Sans serif fonts: Clean lines and bold weights work best.

- Script fonts: Elegant scripts can be used, but make sure they’re not too thin.

- Custom lettering: If you’re aiming for something unique, a custom design can make your embossed material stand out even more.

Avoid thin or delicate fonts, as these may not translate well when raised or indented into the material.

Tips for Getting the Best Embossing Results

- Start with a professional design: Your design needs to be prepared specifically for embossing.

- Use quality materials: For Emboss you can choose from a range of different paper types, we recommend choosing one under 200gsm for best results from this finish.

- Work with specialists: Printers experienced in embossing can help you choose the right finish, pressure, and design setup.

Image Credit: TatianaSoash

Designing for Embossed or Debossed Print

To get the best results, it’s important to prepare your artwork correctly. Here are some do’s and don’ts for designing for embossing and debossing.

DO:

- Leave a 5mm safe area: Keep your embossed or debossed elements at least 5mm away from the edge of the page to avoid any issues during production.

- Use a minimum font size of 8pt: Anything smaller can lose clarity and become unreadable.

- Supply vector files: Artwork should always be in a vector format (like an .ai or .eps file) to ensure clean, crisp lines for the die.

- Choose the right paper weight: For debossing, thicker stocks of 300gsm or more are preferred as they allow for a deeper impression. For embossing, stocks under 200gsm can work well.

- Opt for bold artwork: Both finishes work best with strong, clear lines and bold shapes.

DON’T:

- Highly detailed designs: Complex patterns with very thin lines or tiny type tend to lose their definition.

- Heavily textured paper stocks: A smooth paper will show off the embossed or debossed finish much better. Textured papers can interfere with the clarity of the impression.

Final Thoughts: Embossed vs Debossed – Which One Wins?

Ultimately, the choice between embossing and debossing comes down to your brand’s personality and project goals.

So, which one wins in the embossed vs debossed debate? Neither is universally “better.” The right choice depends on your brand’s personality, project goals, and desired final look.

Both techniques offer a powerful way to elevate your printed products and make them feel more premium and memorable. By adding a tactile dimension, you create a stronger connection with your audience and leave a lasting impression with your print.

It’s important to remember, while the first print run for these special finishes might seem like a bigger investment, we’ve got you covered! We store your die cut blocks safely, making future reorders both cheaper and less wasteful.

Bespoke Service:

Looking to bring your designs to life with a beautifully textured finish?

Our Bespoke Service offers both embossing and debossing. Our dedicated team can help you create a one-of-a-kind product that truly stands out. Simply complete our form with your desired colour and specifications, and we’ll take care of the rest.